What is a Twist Drill?

Twist Drill Definition

Twist drills are the most common types of drill bits. A twist drill has a cylindrical shape with deep helical grooves running lengthwise across its body. It is made up of three major components: the shank, the body, and the drill point.

What is a twist drill used for ?

Twist drills, often known as twist bits, are the most common type of drill bit. They are used to drill holes in materials such as plastic, wood, and steel. However, they are most commonly used for metal cutting, and they are typically made of high-speed steel also known as HSS.

Parts of a Twist Drill

Shank - The shank is the drill's upper cylindrical smooth section utilized to grasp and drive the drill. It is tapered to allow for easy insertion into the drill chuck. The upper end of the shank is sometimes flat and is referred to as the tank

Body - The body of the twist drill is positioned at the bottom end of the drill, running from underneath the shank to the cutting point. It has an upper end with a neck whose diameter is less than the section of the shank above the neck and the rest of the body.

It has several sub-parts, such as flutes. A flute is a deep groove that often wraps around the bit, providing a way for waste material to exit the hole. The flute is sometimes the reason why it is called twist drill.

Drill Point - The point is the cone-shaped sharpened edge of the drill that consists of the flank face and cutting lips. The main cutting edges do the actual drilling. Even though the variations are minor, long cutting edges outperform short cutting edges in terms of cutting performance.

What are drill bits made of?

Drill bit materials

Carbon tool steels are employed in settings where very little heat is created. Drill bits are made from both low and high carbon steel.

Because of its increased hardness and improved wear resistance, High-Speed Steel (HSS) is a favored material for use in drill bits. These characteristics enable drilling at higher speeds and through harder materials.

Cobalt High-Speed Steel (HSS) drill bits contain Cobalt, which increases the material's hardness above ordinary HSS.

Carbide metal drilling bits are ideal for drilling nonferrous metals. Carbide drills will outlast cobalt drills by a factor of 10 or 20. However, a carbide drill might cost nearly ten times the price of a cobalt drill.

Twist Drill Coatings

The surface of drill bits with a bright finish lacks coatings that lengthen tool life and improve cutting effectiveness. The bright finish is the least expensive choice and performs well in some applications.

Black Oxide has an improvement over the bright finish in terms of lubricity. In addition, its additional heat treatment can enhance the life of the drill bit by up to 50% over conventional HSS. Black oxide is not a coating but a heat treatment procedure used on HSS to reduce friction and wear.

Titanium is a corrosion-resistant metal that is utilized as a coating on HSS drill bits to give them extremely high surface hardness levels in the form of titanium nitride, or TiN. Titanium-coated drill bits can drill through difficult materials and last up to six times longer than ordinary HSS bits. You can tell titanium nitride by its bright gold color

The titanium-aluminium-nitride coating (TiAlN) is a versatile and globally applicable coating. TiAlN is a chemical compound made up of titanium, aluminum, and nitrogen. The coating thickness ranges from 1-4 micrometers (m). The coating is resistant to heat and oxidation. This allows for faster cutting speeds and faster work process

Comparison of TiN and TiAlN

|

TiN |

TiAlN |

|

|

Service life is extended as compared to uncoated tools. |

3-4 x longer |

2-7 x longer |

|

Hardness |

2400 – 2600 Hv |

4000 – 4200 Hv |

|

Nano hardness |

24 Gigapascal (GPa) |

35 Gigapascal (GPa) |

|

Coat thickness |

.0001″ – .0002″ (2 to 5 microns) |

0001″ – .0002″ (2 – 5 microns |

|

Deposition Temp. |

700 – 800°F |

700° – 800°F |

Different types of drill bits

Choosing the right drill bit can be difficult because there are many possible alternatives.

High-speed steel drill bits are the most basic and least expensive general-purpose drill bit. It's pretty flexible and can be used for a hand drill as well as a drill press. In addition, they can be resharpened to increase their lifespan.

Cobalt reinforced high-speed steel bits outperform standard high-speed steel drill bits. In addition, cobalt improves high-speed steel's heat and wear resistance. Thus, creating a more robust drill bit that is easy to resharpen.

On the other hand, carbide is the most pricey but also the most durable. Carbide is a tungsten-carbon compound. Carbide drill bits are typically composed of steel that has a carbide tip.

Carbide drills are typically used for difficult-to-drill materials and deeper holes. Carbide also permits coolant to pass through holes placed into the drill. The high-pressure coolant adds lubrication and keeps the cutting zone cooled, reducing wear.

Types of drill bits chart

Here is a table of the different twist drills. If you click on the twist drill in the PDF, you will be directed to the product page, where you can find more information on the twist drill.

How to Use a Drill bit

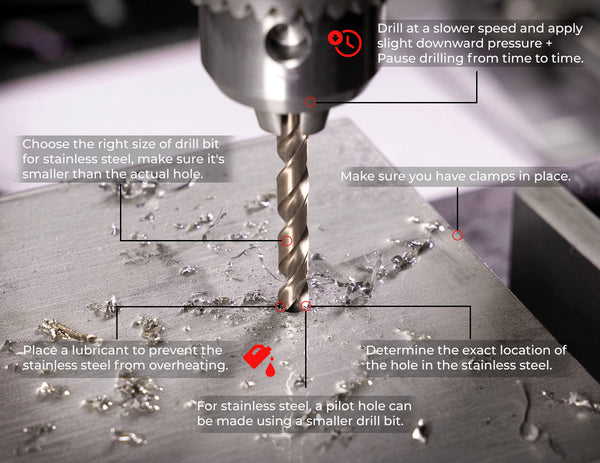

- Clamp the object you want to drill to a stable surface and use a spare piece of plywood underneath to support the portion you are drilling.

- Determine the exact location of the hole in the stainless steel. You can use a pilot hole to guide the maid drill to the hole.

- Apply the proper speed and pressure depending on the material you are drilling.

- While drilling, apply a lubricant to remove unwanted debris and reduce heat, especially when drilling deeper holes. Lubricants such as WD40, canola oil, or even vegetable oil.

- During the drilling process, apply little but firm pressure to the drill.

- Drill manufacturers recommend slowing the feed rate before the drill point breaks through the material to reduce heat.

- Pause or slow down to re-lubricate the drill to prevent it from overheating.

Which is the best drill to buy ?

Please feel free to go through our drill collection. Quality Tools UK only sells the best drills on the market, so you can be sure they will last a long time. However, if you are still unsure whether you need to replace your drills, please contact our experts, who will gladly advise you.

- 0 comments

- Tags: DIY, Drills, Jobber Drills, RUKO, Step by Step Guide/Demonstration, TERRAX, Twist Drills

0 comments